CNC Machine Shop

RUS Industries, Inc., is a general contract machine shop supplying critical components to a wide variety of industries.

A wide range of modern and accurate machining and milling equipment enables RUS Industries to respond quickly and cost-effectively to virtually any project whether it is a large or small quantity.

An experienced management team provides complete support, from engineering, to manufacturing, operations, and quality control.

A talented, non-union work force with over 30 personnel dedicated to machining ensures consistent results and exceptional workflow output.

A 29,000 square foot facility with easy access to interstate highways and shipping services enables rapid turnaround and stable price controls.

Complementary, off-site capabilities streamline multi-step processes, including heat treating, plating, anodizing, polishing, welding, and assembly.

A comprehensive quality control program, including an atmospherically controlled lab and gauges certified and calibrated to National Standards, provides consistent, dependable and precision-crafted components that ensure optimal performance.

CNC Turning Centers Bar Machines

EUROTECH 545 SL-Y

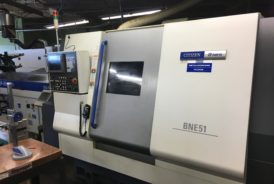

MIYANO BNE 51

MORI SEIKI NL-2000 SY

2-1/2 Bar Capacity, “Y” Axis Turret, Twin Spindle, Live Tooling, Full “C” Axis, Auto Load Bar Feed, High Pressure Coolant

MORI SEIKI NZX1500/800SY2

2″ Bar capacity. Twin turret twin spindle, multi-axis machine with live tooling. Our model is equipped with high pressure coolant and bar feeder.

MORI SEIKI SL-154 SY

1 5/8” Bar Cap. “Y” Axis Turret, Twin Spindle, Auto Load Bar Feed, Live Tooling. Full “C” Axis, High Pressure Coolant (1000PSI).

MORI SEIKI ZL-153 SMC

1 5/8” Bar Cap. Twin Turret, Twin Spindle, Auto Load Bar Feed, Live Tooling. Full “C” Axis, High Pressure Coolant (1000 PSI).

SWISS STYLE TSUGAMI B0206-III

SWISS STYLE TSUGAMI B0326-II

SWISS STYLE TSUGAMI BS20B2

3/4” Bar Cap. 6 Axis, Sub Spindle, IEMCA Autoload Bar Feed.

SWISS STYLE TSUGAMI SS26

26mm Bar Capacity, 8 Live Tools, Bar Loader, High Pressure Coolant

Not shown:

CNC Horizontal Machines

ENSHU GE460H

High output horizontal milling center

MORI SEIKI NHX4000

16 Pallet Capacity, 60 Tool Capacity, 12k RPM, High Pressure Coolant

MORI SEIKI NHX5000

High Output Spindle, 60 Tool capacity, HP Coolant

CNC Vertical Machine Centers

MORI SEIKI DURACENTER

20 X 40 Table, 10,000 RPM, High Pressure Coolant (1000 PSI), 30 ATC, 4th Axis Positioning.

Not shown:

EXCEL PMC 5T-18

16 X 16 X 20, 18 Tool ATC, 4th Axis.

Automatic Screw Machines

DAVENPORT MODEL B

5 Spindle, 13/16 Cap.

Inspection Department

C.M.M.

20″ X 12″ X 10″ Coordinate Measuring Machine.

C.M.M.

60’’ X 40’’ X 38’’ DEA DCC Coordinate Measuring Machine.

INSPECTION DEPARTMENT

Atmospherically Controlled Inspection Laboratory.